By Amila Premakumara / University of Moratuwa /4th year undergraduate

E-mail : Akpremakumara@gmail.com

1.What is 3D Printing?

As the collective term ‘3D print’ implies, it refers to the manufacturing of a 3-dimensional object / element, utilizing a specialized printer of sorts. As the process is usually interpreted by printing layer after another, it is also known as ‘additive manufacturing in the field. The printing material consists of a wide variety of Plastics, Polyethylene, Poly Vinyl Chloride (PVC), Styrofoam, Resin, Steel, Carbon fiber, etc.

The history of the concept of 3-D printing runs back to the 1940s where Murray Lannister describes his theory through a short story (Things Pass By), which then transferred into a practical application in 1980 by Hideo Kodama, where thermoset polymers were employed as the printing material. Even though the utilization was limited to small elements and objects over the next 3 decades, collaboration with software such as Revit, Cad 3-D in recent years has initiated a new perspective, where 3D printing can be utilized in the versatility of possibilities, including the construction industry, which is the primary focus of this article.

2. 3D Printing into Construction Industry

The stepladders of the traditional construction perspective could be shortlisted as followed,

- Clients’ Brief

- Feasibility Analyses

- Design Phase

- Construction Phase

- Hand over and Maintenance

As to the inherent complexities governed in 3,4 stages along with the lack of platforms to incorporate all the necessities in the design phase, the automation was governed to be challenging to be adapted in the construction context. Additionally, the unforeseen difficulties discovered during the construction phase hampered the implementation of stated methods, as the difficulties proved to be random and unpredictable.

However, the improvement and formation of BIM (Building Information Modelling) in recent years has given the leeway of adapting automation, specifically 3D printing into the construction trade. As these software facilitate the capability of handling all the prerequisites, design requirements and most prominently the tests on the 3d Model, the automation has written the industry quite glaringly, throughout the preceding few years.

Companies such as CCC – (Contour Crafting Cooperation), Cybe Constructions, and Apis cor have produced specialized printers for construction printing, firmly establishing the 3D printing building sequence in the marketplace.

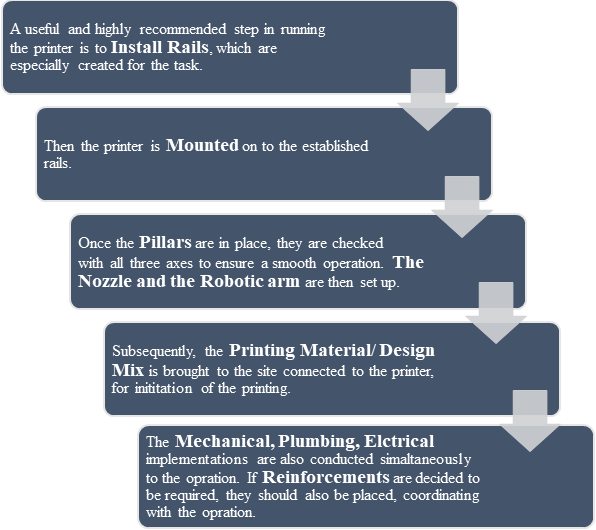

3.Process of 3-D Printing a Structure

3.1 Construction Stage

As discussed previously, seeing a printer in a three-dimensional space provides insight into how this machinery works. However, the printing mechanism employed in the construction sector is not quite similar to the traditional machinery produced since the 1990s. Hence the adapted process also deviates from the known setup, which incorporates the complexity provided by the Finite Element Models (FEM).

Once the model is founded, the design data is converted to Standard Triangle Language (STL), which enables the printer to recognize the design’s complexities and dimensions, as well as the shapes and angles included within.

After the printing head is turned on, external intrusions are limited to a minimum, until the conclusion of the structure. Such process of printing and its’ significant factors can be exemplified as below.

3.2 Utilized Material

3D printing offers the option to use several different types of material, all of which are suitable for printing processes. Depending on the requirements by the client, quality, texture, shape and strength, the material is decided where the nominal practice is to use one such material for the whole operation. Types of such material can be enlisted as follows,

3.2.1 Plastics

Plastic is and will continue to be the primary material driving the 3D printing industry forward in the present and future. Many industry experts and companies favour using plastic in their design aspects due to its’ various achievable colours and textures, Flexibility, Softness and Smoothness, and Rigidity. In the operation, the thermoplastic elements utilized as raw material will be melted and placed in a layered manner.

Another major justification for the use of plastic comprehensively in the reviewing norm is that numerous types of synthesized plastic are available in the market and conveniently synthesizable according to the demand of the structure if required. In response to the industry’s growth over the last several years, companies and academics have developed a series of plastic groups that are excellent for printing, including.

1.Polyastic Acid (PLA)

- Eco Friendly

- Made from organic material (Corn stalks and Sugar Canes)

- Comes in different norms (Smooth, Rigid, etc.)

2.Poly vinyl Alcohol Plastic

- Ideal for low-cost implementations.

- Not recommended for high strength utilizations.

- Dissolvable properties tend to be higher.

3.Acrylonitrile butadiene styrene (ABS)

- Known as ‘LEGO’ plastic as well.

- Good in Strength, Quality and Safety

- Consist of filaments that provides firmness.

- Available in various colours

3.2.2 Powders

Powders are more common to the modern machinery, where it is melted inert the machine and printed in layers to the desired thickness. Alumide and Polyamide (Nylon) are the more common powders are utilized in the industry due to their superior properties in strength, flexibility, and possibility of adapting higher levels of detail.

Not only that, conventional materials such as Copper, Steel and Aluminium are also utilized in 3d printing in the form of powders, However, this is not a typical technique since the melting temperatures of such metals are significantly greater than that of polymers, plastics, or resins.

3.2.3 Resins

Limited material utilized in 3D printing is made from liquidated polymers. These resins generally come in colours Black, White or as Transparent as they are exposed to UV light at the end of the manufacturing process.

3.2.4 Metal

Metals are also popularly exploited materials in 3D printing, also known to be second to the plastics in the trade (Sharrettsplating, 2020). The technique applied in metal printing is identified as Direct Metal Laser Sintering (DMLS). This printing procedure is preferred in occurrences where Strength and Rigidity are critical. Typically, just the essential parts and utilities are printed using metal powders rather than the entire construction. Steel, Copper, Aluminium, Bronze. Nickel and Titanium are generally used it printing such elements.

3.2.5 Carbon Fiber and Graphene

Materials such as carbon fiber and graphene are utilized to address the finishing texture of plastics or other printed components. Specifically, the carbon fibers are laid over the plastic to gain strengthen properties similar to steel as an alternative. On the other hand, Graphene is used in circumstances where conductivity, strength and flexibility are governed in operations.

3.3 General Technology/ Machinery

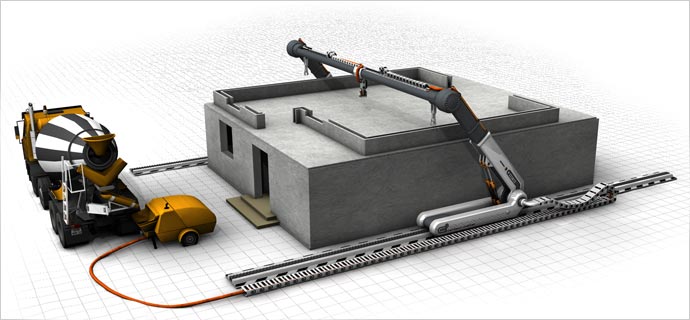

3.3.1 Contour Crafting with Robotic Arm Extruders

Contour crafting is the most common type utilized in the building construction aspect as the cost of implementation, identified to be at a minimum. The extruder arm running on the established rail system, prints the elements, functioning similar to the FDM printer (Fusion Deposition Modelling) in a layered pattern. This concept enables a greater level of efficiency, where a 2000 ft2 house can be printed in less than 24 hours, putting it on par with the best in the industry.

3.3.2 Sand 3D Printing

Differentiating from the conventional types of 3d printing machinery, sand printers exclude the process of heating where the sand-like materials (Silica, Sand, Ceramics) are spread and then held in place/shape using a binding agent. Exclusion of the heat inert the system has allowed the manufactures to come up with the larger devices along with a finer accuracy (600 DPI) which enables efficiency and less time-consuming implementations.

Additional sand on the substrate tends to act as additional supports to the finishing structure, which is proven to be an added advantage. However, at the end of the operation, any presence of loose sand needs to be carefully removed along with the superfluous binder pigments.

3.3.3 Metal Technology in 3D printing

This technique is frequently utilized such as bridges, stadiums, and spanning structures where substantial stress must be dealt with. This is an emerging technique in which printing is combined with six-axis steel welding to produce the desired forms and stress capacities.

Continuous Improvements are made to the printing machinery which unravels the critical challenge of raising productivity in the construction trade, with efficient automation.

4.Advantages of Employing 3D Printing.

4.1 Faster Implementation

In Sri Lanka, it is estimated that it takes around 6-9 months to construct an average house using traditional construction methods. (Ministry of Housing and Urban Development, 2020) However, using 3D printing, a house with the same dimensions can be printed in less than 24 hours, a stunning feat in the building industry.

4.2 Low Cost

Due to the advantages such as low waste, fewer injuries, faster construction rates, the cost of a 3D printed structure has been shown to incorporate a cost much less than the cost of a conventionally constructed structure. Hence the construction companies which have included 3D printing into their operations, have achieved a substantial increase in their profit rates.

4.3 Fewer Injuries

As 95% of the operation is automated, the involvements of the construction workers could be minimized and hazardous circumstances such as working in heights, working in edges, working with sharp machinery can be mitigated, resulting in a lesser number of injuries.

4.4 Waste Reduction

Since these printing processes are fully automated, it allows the constructor to decide the exact amount of material required to finish the structure beforehand, and with that bulk storing of material, reworks, rectifications can be minimized which leads to a much lower wastage compared to conventional constructions.

4.5 Different forms of Structures

High accuracy printers utilized in 3D printers have allowed the designers to work wonders in their structures. As the detailing could be maintained at a level as finer as 600 DPI, a new form of structures has been born having different architectural and aesthetic setups.

4.6 Greater Durability

3D printed structures have identified to have greater durability and resilience against natural adverse effects. (Tornados, Flooding, etc). These properties are inherent in the structures, as the printing process ensures a higher degree in assembling the material. In addition, these structures will require only a few repairs throughout their design life.

4.7 Sustainable Development

Since the amount of material in construction will be minimized along with the wastage, sustainability goals of protecting natural resources are attained.

Additionally, this construction technique does not generate any noise, vibration, emissions, or pollutants in operation, fully conforming to the Green Concept.

Moreover, 3D printing promotes integrated solutions for slums, overcrowding, and disaster relief procedures, as the constructions are less expensive and quicker to execute.

5.Negative Critiques/ Disadvantages upon Implementation

Even though the operation is cost-effective and sustainable, some challenges are remaining to be dealt with, as the technology is yet to be evolved to its full potential. Some of those challenges can be illustrated as,

- New sets of standards, Quality control procedures, Laws and Tests need to be implemented, specifically for 3D printed structures.

- Since it automates the construction process entirely, the unemployment rate will increase with the exclusion of construction workers.

- More complex structures require the printer to be operated throughout the project, which is difficult as it necessitates a comprehensive rail system to run on.

- Post-processing, which means the cleaning up of the loose material is required upon the completion of printing (Sand 3D printers) and it is a delicate process where much time and expertise need to be utilized.

- As these printers operate on a comprehensive detailed set of data produced in the STL language, greater precision is necessary for describing since the margins for rectifications are restricted in 3D printing.

6.Applicability of 3D Printing into Sri Lankan Construction Context and its Importance

6.1 Cost Perspective

Since the Sri Lankan economy is enlisted and operates in a developing perspective, the construction industry alone plays a vital role where 6-9 % of the contribution is provided to the Nation GDP (Gross Domestic Product) of the country. (Oxford, 2016) Thus, advancements in the sector of construction will assure a sustained commitment to the economical growth of the country.

In Sri Lankan context major components in expenditure of a construction project is identified as,

| Component | Cost Fraction (of Total Project Cost) |

| Labour | 0.45 – 0.55 |

| Material | 0.25 – 0.30 |

| Financing | 0.20 – 0.25 |

Adapting 3D printing to the construction industry will benefit all three stated facets as:

- labour costs will decrease as the operation becomes fully automated.

- Material costs will be reduced due to increased efficiency and decreased waste, and

- Financial costs will reduce as the duration of the project decreases.

6.2 Addressing the Housing Requirements

About 800,000 households, with over 21 million people and families of over 6 million living in Sri Lanka, do not have a suitable roof over their heads as a result of the growing shortage of dwellings since 1994. In the Capital of the country Colombo, 1 out of 2 people is a slum dweller without proper access to essential sanitary requirements. (Habitats.org, 2020)

Further, due to the fact that the country was involved in a civil war for almost three decades, many people from the northeastern part of the country have lost their valued residences and have been relocated. (Habitats.org, 2020)

Over the past decade, the country has seen the introduction of several housing projects and initiatives, such as ‘Samata Sevana’ and ‘Uda Gammana’ by the government but has been impeded by the high costs and fewer resources.

In response to the rising population throughout urban regions, both the government and private sector have launched numerous middle-income and luxury apartment projects in the country; nevertheless, statistics indicate that the growth rate is inadequate to satisfy the country’s housing demand. (The Department of Census and Statistics)

As the cost of implementation, material, and financing is much less than for the conventional construction techniques, 3D printing provides a viable alternative in fulfilling the housing demand in Sri Lanka. With the limited versatility of the structures significant, in housing schemes and apartment projects, adaptivity is also highlighted as an excellent feature.

Further, this allows the private sectors and stakeholders to invest in low cost, affordable housing projects, which can be accorded with mortgage options for those in need.

6.3 Addressing the Disaster Aftermath

With the geographical positioning of Sri Lanka being a tropical country with hilly terrains and an island, many types of natural disasters have been recorded over history compared with locked countries. Apart from major earthquakes, Sri Lanka has been victim to many natural hazards such as Extreme Floods (Eastern Province, 1989), Tsunamis (Coastal Region, 2004), Severe Landslides (Meeriyabadda, 2014).

Such hazards leave an aftermath of critical loss of lives and millions of property damage including the devastation of households. As Sri Lanka is already experiencing difficulties meeting household demand inert the country, these sorts of adverse effects aggravate the situation by increasing the necessary number of dwellings.

However, 3D printing of houses can be introduced as a permanent or long-lasting solution for the displaced people from such natural hazards, as the construction time and cost is quite low upon the implementation. This would ensure a suitable living condition for the affected people providing them with physical and mental respite, along the process.

7.Conclusion

3D printing in the construction industry is an emerging field that has successfully increased productivity and sustainability in operations where the cost, time, and utilized resources have been made to be optimum. With the ever-growing technology incorporated with the printing machinery, the possibility of different aesthetic and architectural designs has come to light over the last decade. Even though the concept carries several critiques in the aspects of load-bearing, installing Reinforcements and Services, the improving technique is expected to overcome the said challenges in the next few years.

Concerning to the Sri Lankan construction context and the housing demand within the nation, 3D printed houses proves to be a viable option as it utilizes low cost and time. Further, the challenges from property loss due to adverse natural effects which the country faces continuously can also be addressed quite efficiently over the said aspects. As it also gives the opportuni lower-income families of the country, the efficiency of the implementation could also be expected to be at a maximum.

So, as young civil engineers, it will be our responsibility to make attention to such innovation adaptions, ultimately serving the country as a conscientious product of the public educational system. ty to the private sector to be involved in meeting the housing requirements.

8. References

- Will Concrete 3D Printing Become Standard Practice in Construction? (2018, July 27)

- Giatec Scientific Inc. https://www.giatecscientific.com/education/concrete-3d-

- What Materials Are Used for 3D Printing? (2018, February 19). Sharretts Plating Company. https://www.sharrettsplating.com/blog/materials-used-3d-printing/#:~:text=Out%20of%20all%20the%20raw%20materials%20for%203D

- (PDF) A tool to assess construction worker productivity. (2018, May 20). ResearchGate. https://www.researchgate.net/publication/329069700_A_Tool_to_Assess_Co nstruction_Worker_Productivity

- Building Construction. (n.d.). CC Corp. https://www.contourcrafting.com/building-construction

- printing-may-soon-become-standard-practice-in-construction

- 3D Printed Concrete Buildings- Working & Features – The Constructor

- 8 Ways 3D Printing Has Transformed the Construction Industry (giatecscientific.com)

- All3DP. (2019). Sand 3D Printer – What Exactly Is It? [online] Available at: https://all3dp.com/2/sand-3d-printer-what-is-it/.

- 3D printing for construction and architecture: The Ultimate Guide 2020. (2021).

- 3D printing in construction. (2014). Designingbuildings.co.uk.https://www.designingbuildings.co.uk/wiki/3D_printing_in_construction

- TWI. (2020). What are the Pros and Cons of 3D Printing? Twi-Global.com. https://www.twi-global.com/technical-knowledge/faqs/what-is-3d-printing/pros-and-cons